-

Are you keeping your corrosion surveys separate from your inline inspections?

- Are you missing out on information that may identify deficiencies in your CP?

- Do you lack visibility into your corrosion control program?

The External Corrosion (EC) Module for Close Interval Surveys (CIS) is available with the release of CIM 3.43, scheduled for this month, January 2025. The development team has been working closely with corrosion SMEs to design and implement a module dedicated to managing and analyzing corrosion control data. Assessment planning and analysis are available for Close Interval Surveys as part of Phase 1 of the EC module development, and functionality for additional surveys is currently being developed.

How does it work?

A Close Interval survey (CIS) can now be managed in CIM using the same processes as inline inspections. First, a CIS assessment is planned in the Assessment Planning (AP) process within CIM. Upon uploading the CIS report into the platform, the CIS data is aligned with inline inspection and pipeline data.

Then, the data can be analyzed using the Integrity Compliance or assessment analysis process within CIM. Pre-built conditions are available to analyze the CIS data where a condition is a criterion or set of multiple criteria that CIM utilizes to analyze the CIS readings. For example, a commonly used condition when analyzing inline inspection data is identifying any metal loss that has a depth of 80% or greater. Basic and advanced CIS conditions created by our data science team are available for selection when running an analysis. Integrating the CIS data with pipeline data, such as the location of foreign line and powerline crossings, allows the use of advanced analysis conditions that can identify stray current pick-up and drop-off locations, for example.

Pre-built Analysis Conditions

Examples of Basic CIS Conditions

- Off > -0.850 V: identifies where the “instant off” potential reading is more positive than -850 mV.

- Native Off < 0.100 V: identifies where the difference between the “instant off” potential and native potential is less than 100 mV.

- On < -2.500 V: identifies where the CP potential exceeds (is more negative) than -2500 mV.

Examples of Advanced CIS Conditions

- Under-sampled region: the sampling length needed to conduct a CIS varies, depending on whether the pipeline is coated, the size of coating holidays, the depth of cover, and the resistivity of the surrounding soil. For example, shallow pipelines may need shorter survey intervals, while potential changes are difficult to discern when the pipe is directionally drilled through bedrock, i.e., soil resistivity is high. Drawing on two different calculations referenced in Section 5.6 of the CP-3 Cathodic Protection Technologist manual published by NACE International in 2005, the sampling adequacy is determined, and any regions where the readings need a shorter interval than what was achieved are identified.

- Current Drop-off Locations: This identifies valleys in CP “On” and CP “Instant Off” readings within 500 ft of each other and 100 ft of a foreign line crossing, powerline crossing, or road.

Any regions identified by the analysis can then be selected for remediation within CIM and sent for approval using CIM’s built-in workflow processes. The regions can also be downloaded to a file with location information for corrosion technicians or contractors.

What does it mean? The Value Added

One application to rule them all! (Come on, we know you love this reference.) But seriously, the EC Module provides a means to analyze your cathodic protection readings and inline inspection data in one platform. The platform automatically aligns these previously disparate data sets which means saving valuable time on data integration processes that are currently manual. It also means effectively managing your corrosion data and managing associated remediation tasks. Now you can focus on extracting as much information from your corrosion surveys as possible. (If you’re going to make someone walk your pipeline, this is the least you can do!) Keeping corrosion control data in CIM can also make feeding data into the risk management module (launching soon in CIM) much more manageable!

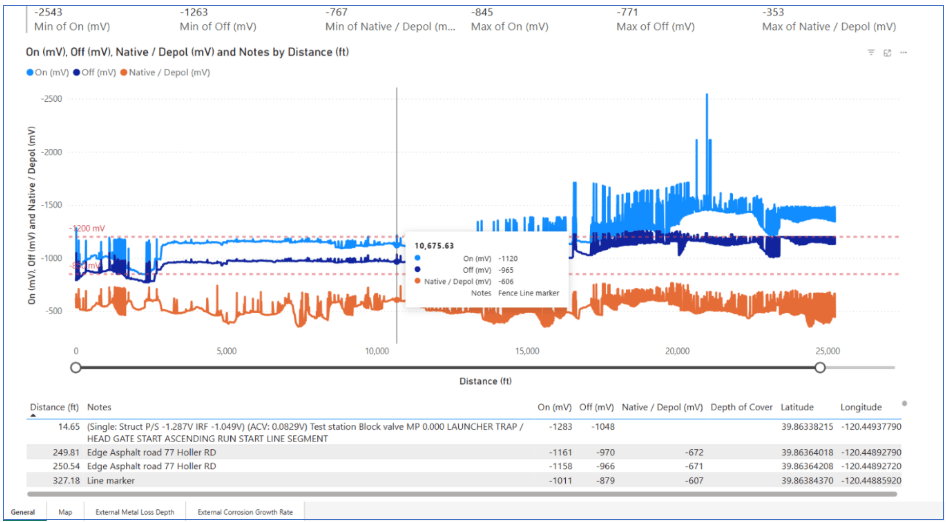

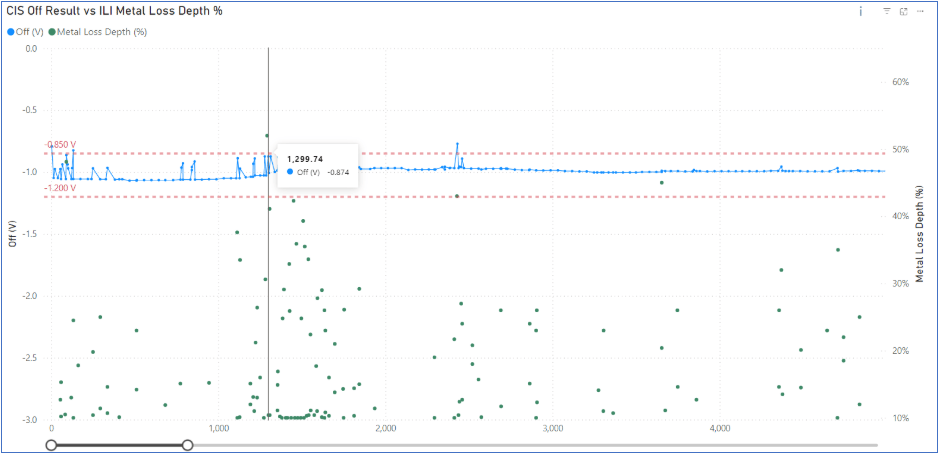

The following figures show screenshots of some reports currently available in the EC module.