Pipeline Integrity, Data Science

Probabilistic Corrosion Growth, Presented at PRCI REX 2025

A New Model for Calculating Probabilistic Corrosion Growth

During this year’s Pipeline Research Council International (PRCI) Research Exchange held in Houston, TX, USA, Irth Solutions presented the “Analytic Derivation and Validation of a Probabilistic Corrosion Growth Model,” which extended research conducted by PRCI. This presentation discussed a model that was designed to provide estimations of metal loss depths at future times without relying on calculating a corrosion growth rate. This probabilistic model makes use of all historical inline inspection (ILI) provided depths and accounts for ILI sizing accuracy without the use of Monte Carlo (MC) simulations.

Impetus

Many corrosion models employed by the industry currently ignore uncertainties in ILI depth measurements. However, best practices and US regulations require that uncertainties be accounted for in reported ILI results per §192.937(c), §192.712(e), and §195.416(c).

Additionally, the common two-point model for calculating a corrosion growth rate (CGR) may penalize operators by yielding more uncertain results or requiring operators to choose specific ILI results and discarding the rest of the available information.

Although complex models have been developed that utilize Monte Carlo (MC) simulations to provide more accurate CGRs, these models require extensive computational power and time.

Derivation

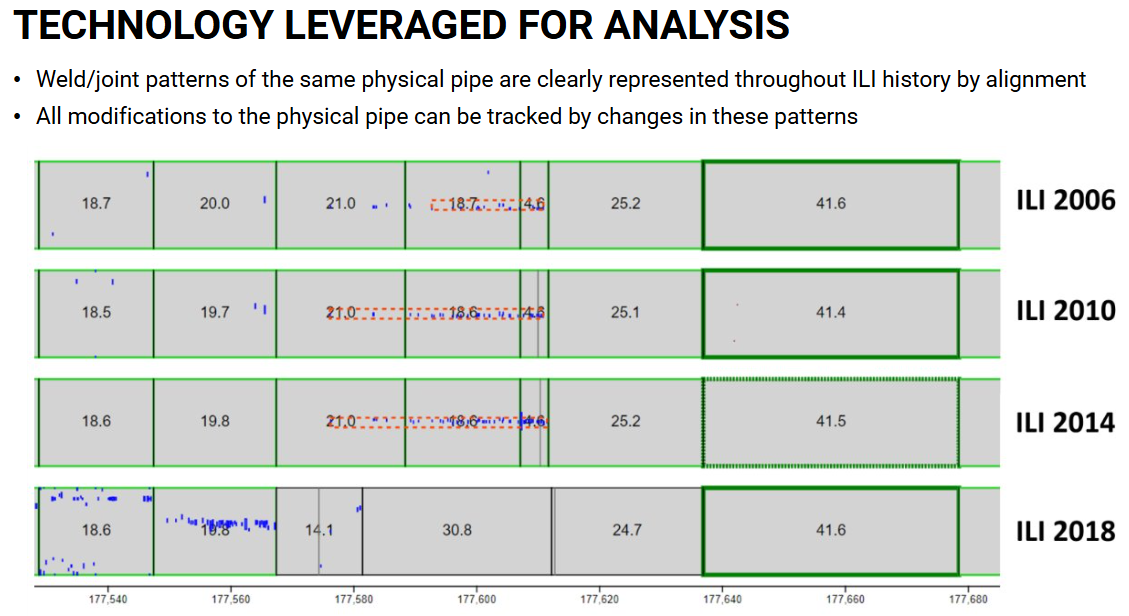

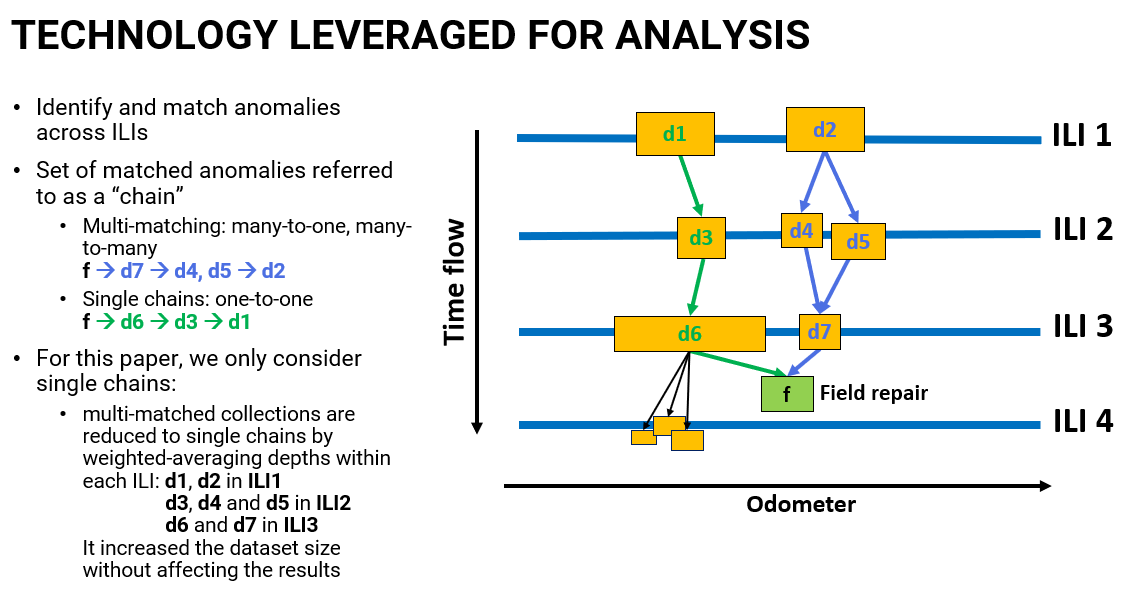

Inline inspection data from 1,294 assessable pipeline segments across four (4) major pipeline operators were analyzed, specifically targeting those pipelines that had three (3) or more ILI runs. Anomalies were automatically matched between the data sets using our Cognitive Integrity Management (CIM) platform. These matched anomalies are referred to as chains: single chains are one-to-one matched anomalies, and multi-matching chains are when many-to-one or many-to-many anomalies are matched. Anomalies used to derive the probabilistic model needed to be:

- Matched anomalies

- Over 3 ILI runs

- Where the final matched anomaly is linked to a field repair in CIM

These requirements provided a total of 1,821 single and multi-matched anomaly chains on 351 pipelines.

Linear (Deterministic) Models

The simplest corrosion growth rate is the two-point model, where the CGR is determined by the depth difference between two ILI readings and the time elapsed. This model can yield overestimated or negative CGRs, limiting its applicability and necessitating corrections.

The all-point model approximates the CGR using more than two ILIs where a linear regression is fit to all measurements via a least squares method. This provides a more accurate but less conservative estimate of a future corrosion depth.

The main drawback to these methods is that they have no way of assigning uncertainty to the calculated CGR or the predicted depth. And in many cases, Monte Carlo simulations show that true probability distributions of CGR and depth are very wide.

Probabilistic Model Overview

The model derivation relied on an extension of the growth model described in PRCI-331. The PRCI-331 growth model is based on the integration of all the allowed ways true depth “d1” can grow to true depth “d2” given measured depth values, their tolerances, and the fact that the growth cannot be negative. The integration is performed numerically using MC simulations where a CGR can be calculated using an equation based on either normal or Weibull distributions.

Whereas the PRCI model makes use of two-point inputs and MC simulations, the model derived for this study can predict a future depth without MC simulations based on any number of ILI measurements. This allows for scalability, as the CIM platform has encountered pipelines with millions of matched anomalies.

This model relies on the assumption of normally distributed depth errors and statistical independence of successive ILI measurements. Results were numerically validated using MC simulations.

CGR and Depth Distributions

A comparison was conducted to compare the probabilistic model using only 2 ILI measurements versus the whole history. The use of only two points leads to higher uncertainty and considerable variation in the projected future depth, as compared to the use of the entire history. There was excellent agreement between the probabilistic/analytical model and the MC simulations.

Integrating a distribution allows operators to assign a probability to have an X% depth, i.e., customize the level of uncertainty by selecting desired percentiles from the distribution. A probability distribution can also be seamlessly integrated into other calculations to analyze risks.

Model Performance

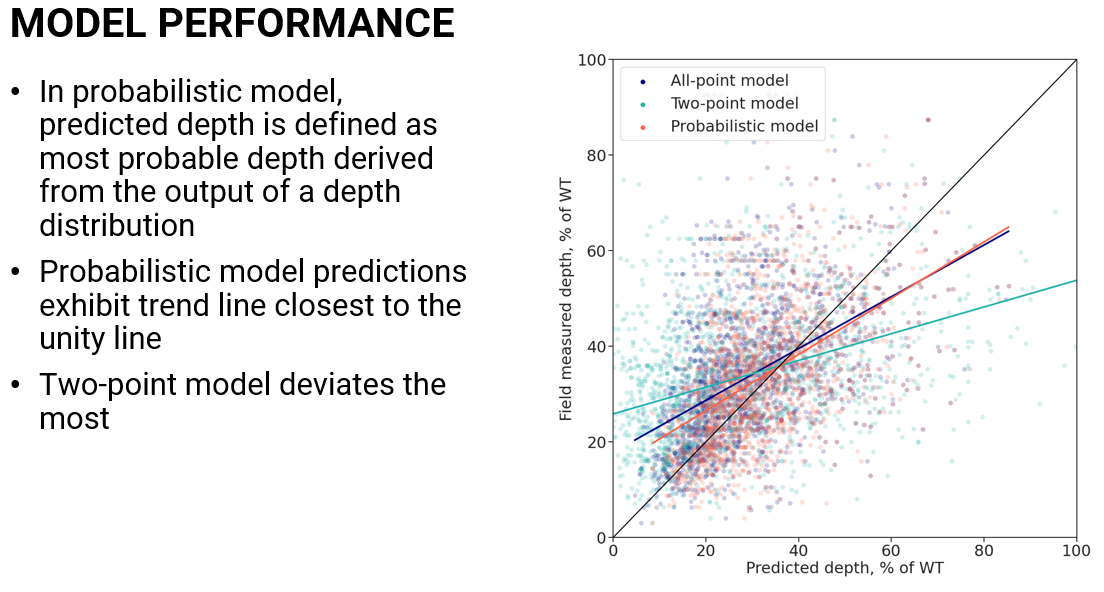

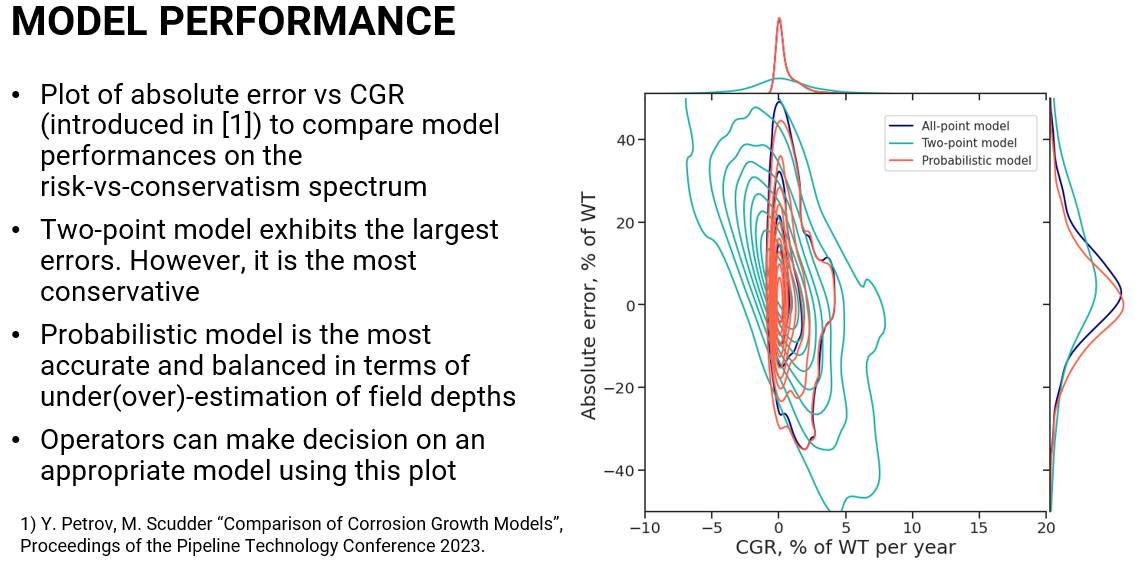

Future depths were calculated using the two linear (deterministic) models as well as the probabilistic depth model. They were compared to the field-measured, sometimes referred to as “actual” values, on a unity plot. This comparison can be seen in Figure 3 below, which demonstrates that the probabilistic model predictions exhibit a trend line closest to the unity line. The two-point model deviates the most. In comparing estimated corrosion growth rates, the probabilistic model is the most accurate and balanced in terms of under(over)-estimation of field depths.

Conclusion

A probabilistic corrosion model that benefits from using the entire ILI depth history and its uncertainties was introduced. This analytical model allows for a scalable, fast implementation. This probabilistic corrosion depth model was validated using MC simulations to produce results that were identical to the precision of MC. Additionally, comparisons of estimated “future” depth with field measurements provided additional validation. Compared to other models, this model exhibits the highest accuracy and is well-balanced on the risk-vs-conservatism spectrum. Operators can use the future depth probability distribution from the model as a direct input to other calculations. For example, when calculating the remaining life or confirming the pipeline reinspection interval, – instead of using future depth provided by a deterministic CGR, one can use the most probable depth when calculating the burst pressure at a future time for increased accuracy.

Overall, the model provides:

- Depth probability distribution at any future time, to be used directly (without relying on CGR).

- CGR probability distribution at the time of the latest ILI, if needed

- A rigorous way to assign errors on future depth and to calculate the probability of depth values

Click here to download the paper presented at PTC 2024.

Fill out the form below to download a copy of the PRCI REX 2025 Presentation.